Certifications

Certificates are earned by passing a competency-based online exam, administered at one of the YMU-approved testing centers.

Testing centers can be established in current K-12, post-secondary, and continuing education institutions.

Contact 1-800-854-4876, option 3

- To find a testing center near you

- To have a potential testing center approved by YMU

Yamaha Marine University (YMU) offers national certifications to career and technical education students, incumbent workers, and people starting their next career. Earning a YMU certification gives the person the knowledge they need to be successful in the marine industry and validates they have met the standards of the industry to employers.

YMU offers four standards-based certificates that validate essential knowledge, skills, and abilities required to be a maintenance-qualified Marine Engine Technician.

Certifications Purpose

To assess the mastery of maintenance tasks associated with marine engines per the service interval requirements in applicable service manuals for 20 to 1000 hours of engine operation.

When a technician passes the YMU maintenance certification exam, marine service employers can feel confident the certified technician can demonstrate proficiency in real-world, marine service competencies.

Preparation

To prepare to earn a YMU certification, candidates are encouraged to:

- Complete a minimum of 150 hours of marine-service instruction

- Have a minimum of two years of experience in the field as a marine technician

Candidates should contact YMU at 1-800-854-4876, option 3 to:

- Register for the exam

- Locate a testing center and check available testing dates

- Access test preparation materials Benefits of Certification

Certification Categoriees

Portable Outboard Maintenance

Competencies assessed:

- Use applicable Service Manual and related resources/tools for portable models.

- use the maintenance charts inapplicable Service Manual for portable models.

- check and adjust valve clearance. spot issues while performing regular maintenance tasks.

- inspect and replace spark plugs. changing engine oil using drain plug or extraction pump. recommend and use the correct oil and lubricants.

- properly drain and refill lower gear lubricant. inspect and replace water pumps.

- remove and reinstall lower units.

- check power tilt and manual tilt operation.

- inspect and replace anodes.

- inspect and replace fuel filters and fuel pump.

- conduct a compression test.

- test fuel components on and off the engine.

- remove and check fuel pump assembly.

- inspect and replace timing belt.

- inspect tiller handle operation.

- inspect and adjust throttle/shift cables.

- inspect and replace propellers.

- create and submit a parts pick list.

- grease points and inspect cowlings.

- inspect and replace marine batteries.

- the importance of service literature

- when and what to perform routine service on

- the importance of service

- the basic attributes of the propeller and what moves it

- fuel problems and resolutions

Midrange Outboard Maintenance

Competencies assessed:

- use applicable midrange service manual and related resources/tools.

- use the maintenance charts in applicable midrange service manual.

- inspect and replace marine batteries. grease points / cowling and tilt operation.

- inspect and replace spark plugs/spark plug cap/ignition coil.

- Vapor Separator Tank/fuel system

- inspect and replace thermostat.

- inspect and replace timing belt. inspect and adjust valve clearance.

- Select an area to comment on inspect and adjust throttle/shift cables.

- check tiller handle operation.

- inspect and replace propellers.

- create and submit a parts pick list.

- replace oil by draining and replace oil by using an extraction pump.

- inspect and replace water pumps.

- conduct pressure tests.

- spot issues while performing regular maintenance tasks.

- recommend and use the correct oil and lubricants.

- properly drain and refill lower gear lubricant.

- remove and reinstall lower units.

- check power tilt and hydro tilt operation.

- inspect and replace anodes.

- inspect and replace fuel filters and fuel pump.

- conduct a compression test.

- test fuel components on and off the engine.

- remove and check fuel pump assembly.

- inspect and replace timing belt.

- the importance of service literature

- when and what to perform routine service on.

- the importance of service the basic attributes of the propeller and what moves it

- fuel problems and resolutions

Inline Outboard Maintenance

Competencies assessed:

- use the applicable inline service manual and related resources/tools.

- use the maintenance charts in applicable inline service manual.

- inspect and replace marine batteries.

- grease points / cowling and tilt operation.

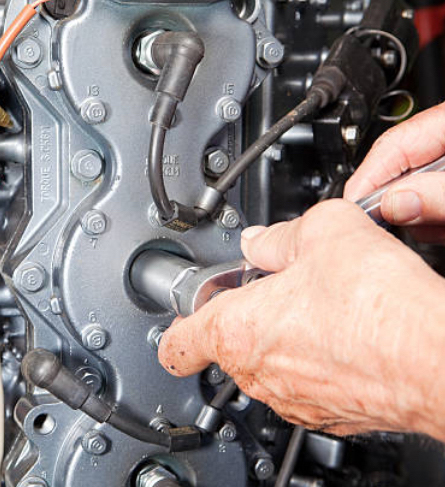

- inspect and replace spark plugs/spark plug wire/ignition coil.

- Vapor Separator Tank/fuel system inspect and replace thermostat and PCV.

- inspect and replace timing belt.

- inspect and adjust valve clearance.

- inspect and adjust throttle/shift cables/cable joint to specs using digital caliper.

- inspect and replace propellers.

- create and submit a parts pick list.

- replace oil by draining and replace oil by using an extraction pump.

- inspect and replace water pumps.

- conduct pressure tests.

- spot issues while performing regular maintenance tasks.

- recommend and use the correct oil and lubricants.

- properly drain and refill lower gear lubricant

- remove and reinstall lower units.

- check PT&T operation. inspect and replace anodes.

- inspect and replace fuel filters and fuel pump.

- conduct a compression test.

- test fuel components on and off the engine.

- remove and check fuel pump assembly.

- inspect and replace timing belt.

- the importance of service literature

- when and what to perform routine service on

- the importance of service

- the basic attributes of the propeller and what moves it.

- fuel problems and resolutions

V-Engine Outboard Maintenance

Competencies assessed:

- use applicable V-engine service manual and related resources/tools.

- use the maintenance charts in applicable V-engine service manual.

- inspect and replace marine batteries.

- grease points / cowling and tilt operation

- inspect and replace spark plugs/ignition coil.

- Vapor Separator Tank/fuel system inspect and replace thermostat.

- inspect and replace timing belt.

- inspect and adjust valve clearance.

- inspect and adjust throttle/shift cables/cable joint to specs.

- inspect and replace propellers.

- create and submit a parts pick list. change the oil.

- inspect and replace water pumps.

- conduct pressure tests.

- spot issues while performing regular maintenance tasks.

- recommend and use the correct oil and lubricants.

- properly drain and refill lower gear lubricant.

- remove and reinstall lower units.

- check PT&T operation.

- inspect and replace anodes.

- inspect and replace fuel filters and fuel pump.

- conduct a compression test.

- the importance of service literature

- when and what to perform routine service on

- the importance of service

- the basic attributes of the propeller and what moves it

- fuel problems and resolutions